Driveline Angle Worksheet

Driveline Angle Worksheet - A universal joint operating angle is the angle. For each of the following values,. + _ length(in) to measure driveline length: Any angle measured that runs downhill from front to back. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! Imbedded support for many commonly used driveshaft and axle models (35 driveshaft models, 53 single axle.

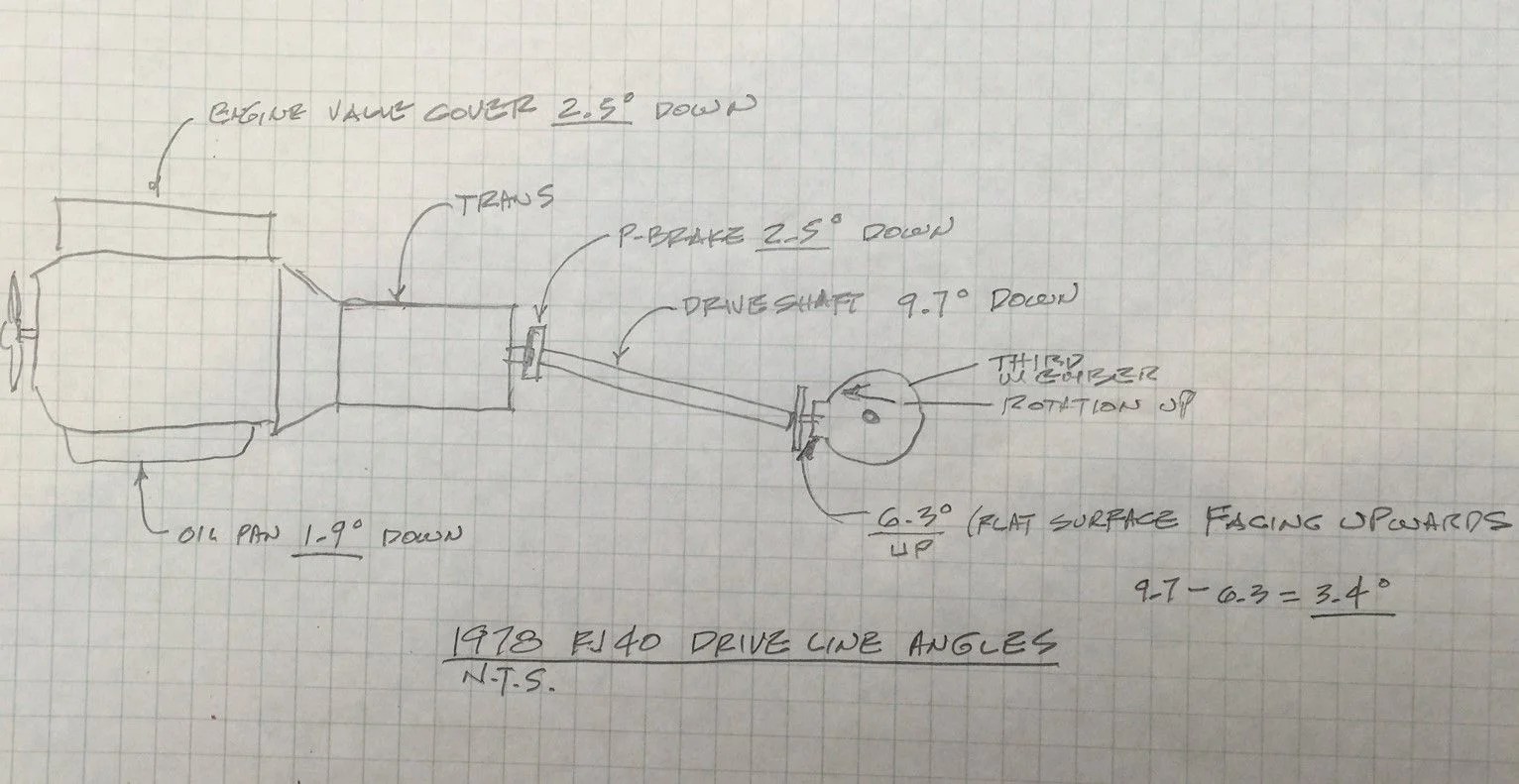

Printable worksheets to aide in collecting the needed driveline measurements. This article provides information to properly check driveline angles and driveline runout, and how to use that information to properly repair the vehicle and bring the driveline. Operating angles in a driveshaft are the angles between the pinion, driveshaft and transmission centerlines. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! Any angle measured that runs downhill from front to back.

+ _ length(in) to measure driveline length: The optimal angle for any driveshaft to run at is 1/2 degree, where many. This video offers a quick tutorial that can makes measuring driveline angles a snap. Read and understand all instructions and procedures before you begin to service components.

Select the number of shafts in your application. + _ length(in) to measure driveline length: When you rework a chassis or install a new driveshaft in a vehicle , make sure that you follow the basic rules that apply to uni versal joint operating angles: For each of the following values, enter angle (to the nearest 1/4 degree) and slope.

This 101 course will help you measure and correct your driveline. Imbedded support for many commonly used driveshaft and axle models (35 driveshaft models, 53 single axle. When you rework a chassis or install a new driveshaft in a vehicle , make sure that you follow the basic rules that apply to uni versal joint operating angles: The optimal angle.

Select the number of shafts in your application. This video offers a quick tutorial that can makes measuring driveline angles a snap. Imbedded support for many commonly used driveshaft and axle models (35 driveshaft models, 53 single axle. When you rework a chassis or install a new driveshaft in a vehicle , make sure that you follow the basic rules.

When you rework a chassis or install a new driveshaft in a vehicle , make sure that you follow the basic rules that apply to uni versal joint operating angles: This article provides information to properly check driveline angles and driveline runout, and how to use that information to properly repair the vehicle and bring the driveline into specification. Measure.

Read and observe all warning and caution hazard alert messages in this publication. Printable worksheets to aide in collecting the needed driveline measurements. Select the number of shafts in your application. Select the number of shafts in your application. Any angle measured that runs downhill from front to back.

A universal joint operating angle is the angle. Select the number of shafts in your application. Printable worksheets to aide in collecting the needed driveline measurements. Read and observe all warning and caution hazard alert messages in this publication. This article provides information to properly check driveline angles and driveline runout, and how to use that information to properly repair.

Operating angles in a driveshaft are the angles between the pinion, driveshaft and transmission centerlines. Measure the following angles, using the chart below for reference. Any angle measured that runs downhill from front to back. Select the number of shafts in your application. This 101 course will help you measure and correct your driveline.

Driveline Angle Worksheet - Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! Correct universal joint operating angles are crucial in preventing torsional and inertial effects, which create vibrations that can damage many of the driveline components in your vehicle. Operating angles in a driveshaft are the angles between the pinion, driveshaft and transmission centerlines. + _ length(in) to measure driveline length: Any angle measured that runs downhill from front to back. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). Read and understand all instructions and procedures before you begin to service components. This article provides information to properly check driveline angles and driveline runout, and how to use that information to properly repair the vehicle and bring the driveline into specification. Read and observe all warning and caution hazard alert messages in this publication. Imbedded support for many commonly used driveshaft and axle models (35 driveshaft models, 53 single axle.

For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). When you rework a chassis or install a new driveshaft in a vehicle , make sure that you follow the basic rules that apply to uni versal joint operating angles: This article provides information to properly check driveline angles and driveline runout, and how to use that information to properly repair the vehicle and bring the driveline into specification. This 101 course will help you measure and correct your driveline. If the coupling angle of the shaft exceeds 3.0°, the life of the universal joint.

A Universal Joint Operating Angle Is The Angle.

Printable worksheets to aide in collecting the needed driveline measurements. The optimal angle for any driveshaft to run at is 1/2 degree, where many. Measure the following angles, using the chart below for reference. Read and understand all instructions and procedures before you begin to service components.

This Video Offers A Quick Tutorial That Can Makes Measuring Driveline Angles A Snap.

Correct universal joint operating angles are crucial in preventing torsional and inertial effects, which create vibrations that can damage many of the driveline components in your vehicle. Read and observe all warning and caution hazard alert messages in this publication. Select the number of shafts in your application. This 101 course will help you measure and correct your driveline.

A Worksheet To Assist With Recording Values Can Be Found Here:

Operating angles in a driveshaft are the angles between the pinion, driveshaft and transmission centerlines. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). If the coupling angle of the shaft exceeds 3.0°, the life of the universal joint. For each of the following values,.

When You Rework A Chassis Or Install A New Driveshaft In A Vehicle , Make Sure That You Follow The Basic Rules That Apply To Uni Versal Joint Operating Angles:

This article provides information to properly check driveline angles and driveline runout, and how to use that information to properly repair the vehicle and bring the driveline. Driveline angles can be the difference between a smooth ride and your teeth vibrating out of your skull! Select the number of shafts in your application. + _ length(in) to measure driveline length: